SuperDesk - Split Hinged Front Lid

SuperDesk - Split Hinged Front Lid

Standard Features

Standard Features

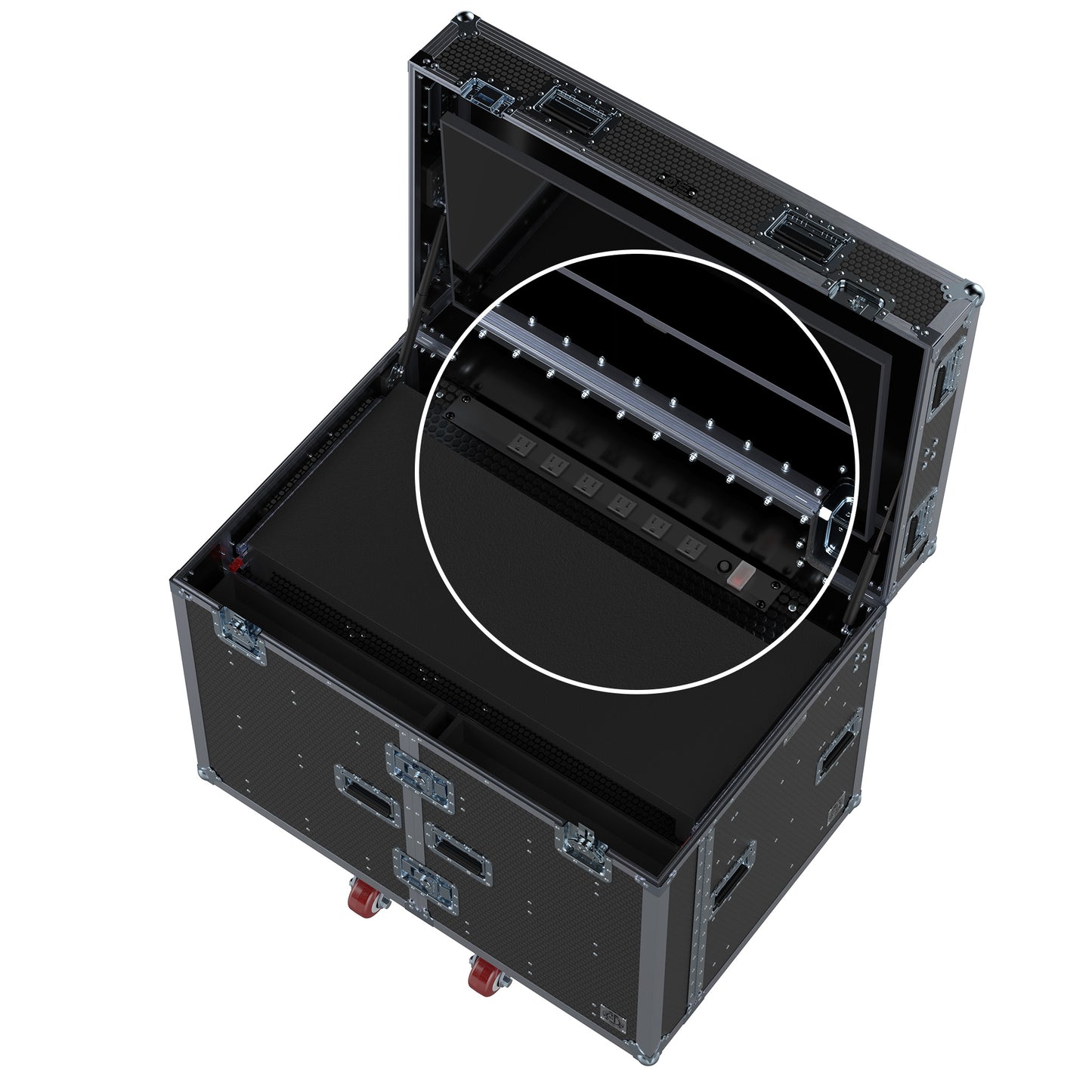

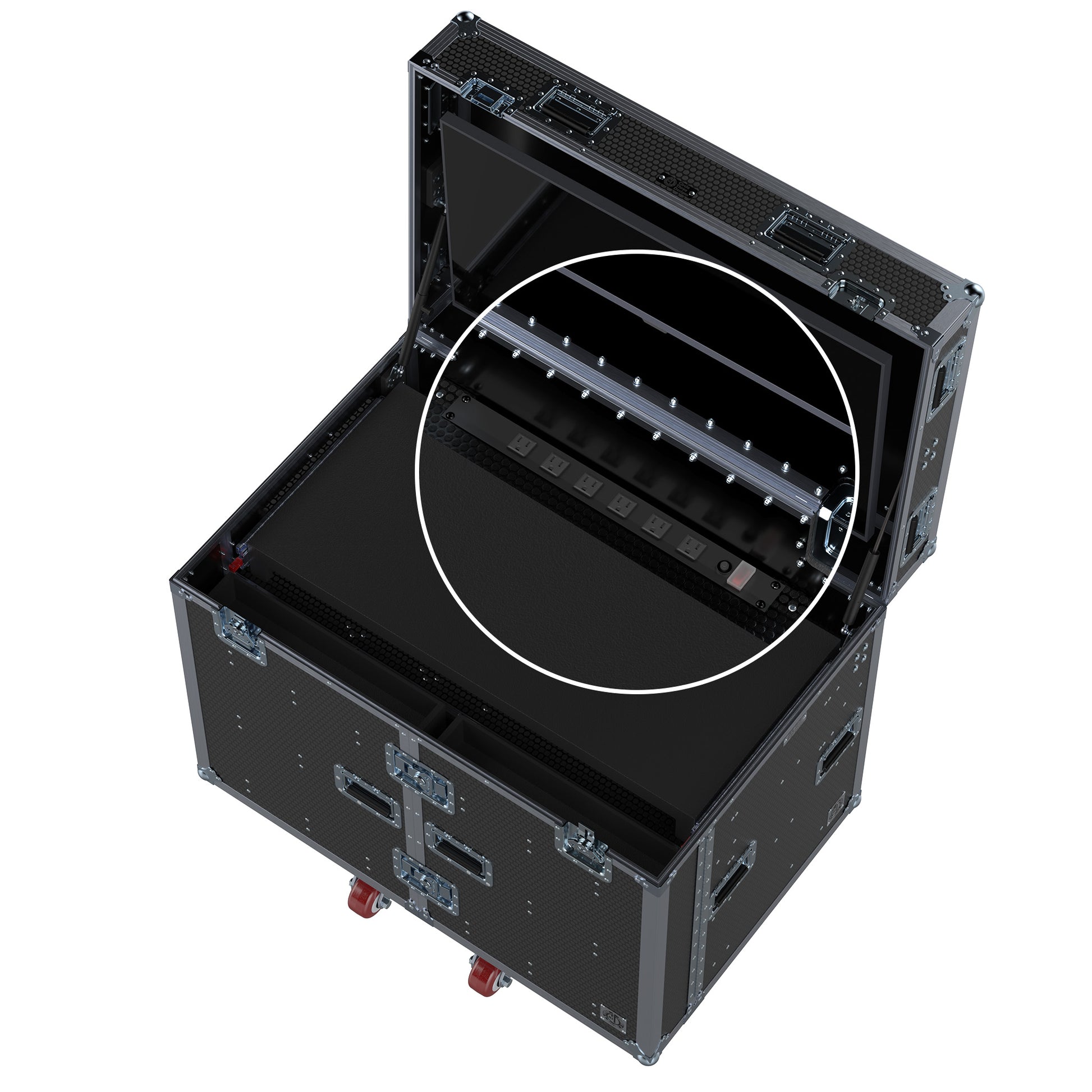

Design: Flip-top lid with a split-hinged front lid with cubbies.

Dimensions: Designed with "truck pack friendly" dimensions. These cases are designed with a 45" x 30" footprint.

Handles: 14 recessed handles.

Latches: 4 recessed latches (one pad-lockable).

Label Dish: 1 recessed label dish (perfect for dry-erase PAL labels).

Corners: Ball corners are used on these cases in order to take the brunt of the abuse and protect the actual case.

Casters: Six extra heavy duty 4" casters (non locking) each rated at 750 pounds. All cases come with a full length 3/4" Baltic Birch caster pallet.

Case Construction

Case Construction

Material: 1/2" Finnish Birch plywood with black phenolic resin. This 100% Finnish Birch plywood is made specifically to our specifications. The exterior phenolic resin has a “circle grip” pattern compared to the typical “haircell” pattern found on ABS. Unlike ABS, the phenolic resin will never delaminate.

Extrusions: Double angle extrusion is used to join the panels of the case together. It has a channel that the Finnish Birch plywood lives in. This is superior to single angle extrusion which is simply a piece of right angle aluminum that covers the corner. Double angle extrusion makes for a better, stronger and more durable case. Tongue and groove extrusion is used around the edge of the case where the lid meets the body.

Rivets: All of the rivets are backed by steel washers. Without washers, the rivets will eventually loosen and the case can fall apart.

Welding: The tongue and groove extrusions are welded at key joints in order to significantly strengthen the case. This helps to keep lids closing easily despite years of abuse on the road.

CNC / CAD: Every case starts off life as a detailed CAD model before it hits the manufacturing floor. Panels are precisely machined using state of the art CNC technology affording us the ability to consistently provide uniformity and repeatability. Aluminum extrusion lengths are calculated using CAD modeling systems to ensure a proper fit and are cut using digital technology.

Drawers and Dividers

Drawers and Dividers

Drawers: Drawers are made out of 1/2" Baltic Birch plywood.

Handles: Slam latches are used as handles to prevent the drawers from inadvertently opening.

Slides: Drawer slides are rated at 200 pounds.

Dividers: Dividers are made out of 1/2" Finnish Birch plywood and capped off with aluminum U channel. Dividers between each drawer strengthen the case by making it more rigid.

Work Surface and Flip Top Lid

Work Surface and Flip Top Lid

Flip-Top Lid: Black phenolic resin interior with hardware and aluminum extrusion visible.

Surface: Multiple sliding work surface options that locks in the "in" and the "out" position on slides that are rated at 450 pounds:

Flat sliding work surface.

Step down sliding work surface.

Standing desk height-adjustable insert built into the sliding work surface.

Power: Recessed power distributer on the work surface with 6 Edison outputs. Recessed dish on the exterior of the case with powerCON-in and powerCON-out allowing multiple workstations to be linked together and powered from one source. Recessed dish on the exterior of the case with two blank Neutrik D punchouts for future expansion.

Additional Options

Additional Options

- Chief Fusion Series Tilting TV mount (max size 43").

- Chief Kontour Dynamic Height-Adjustable monitor mount (max size 27")

- 4 extra heavy duty locking casters

- Individual drawer locks.

- Safe mounted in drawer.

- Sliding printer tray that locks in the "in" and the "out" position. Designed for the HP ENVY 6055e All-in-One Printer.

- 43" TV and/or HP ENVY 6055e printer can be provided and installed.