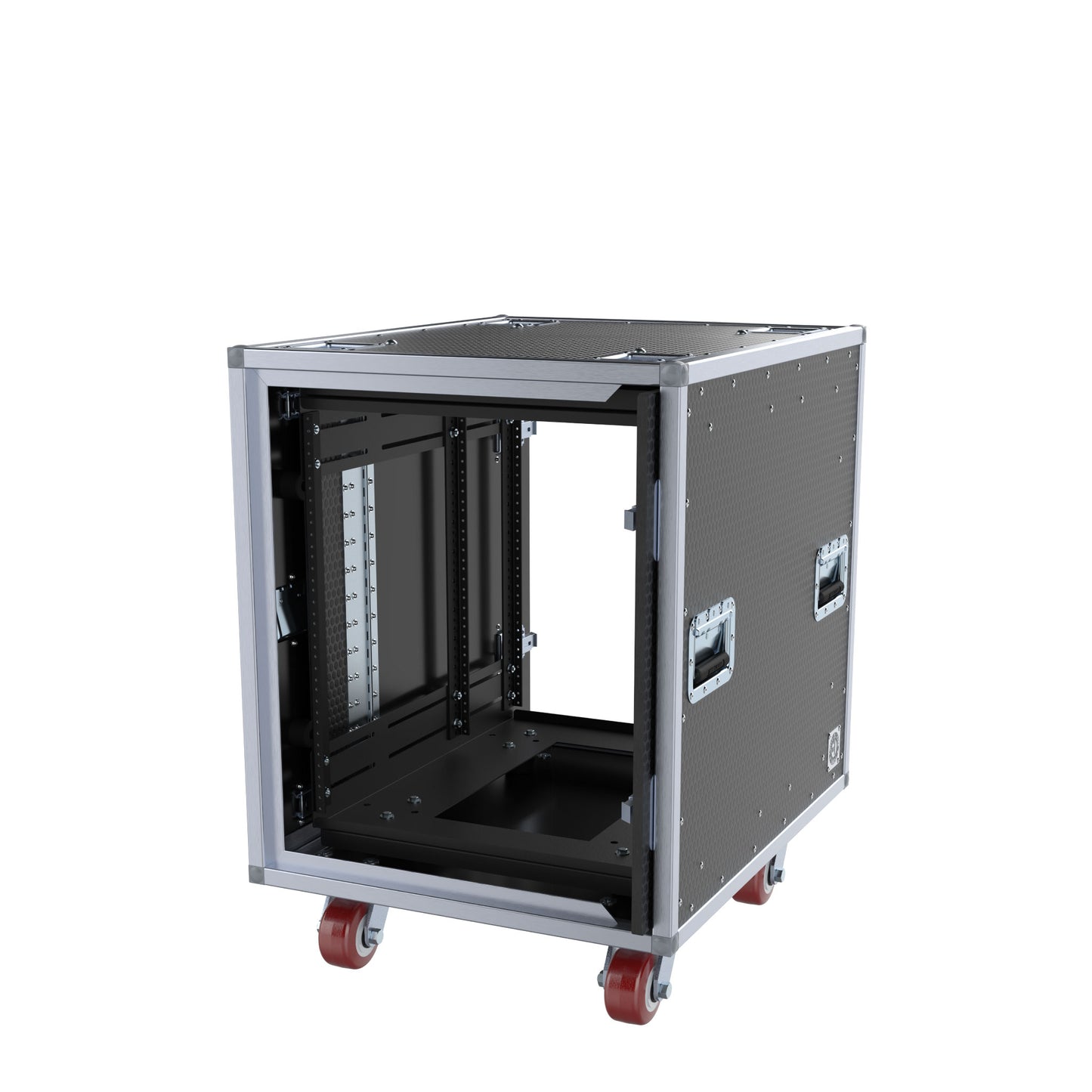

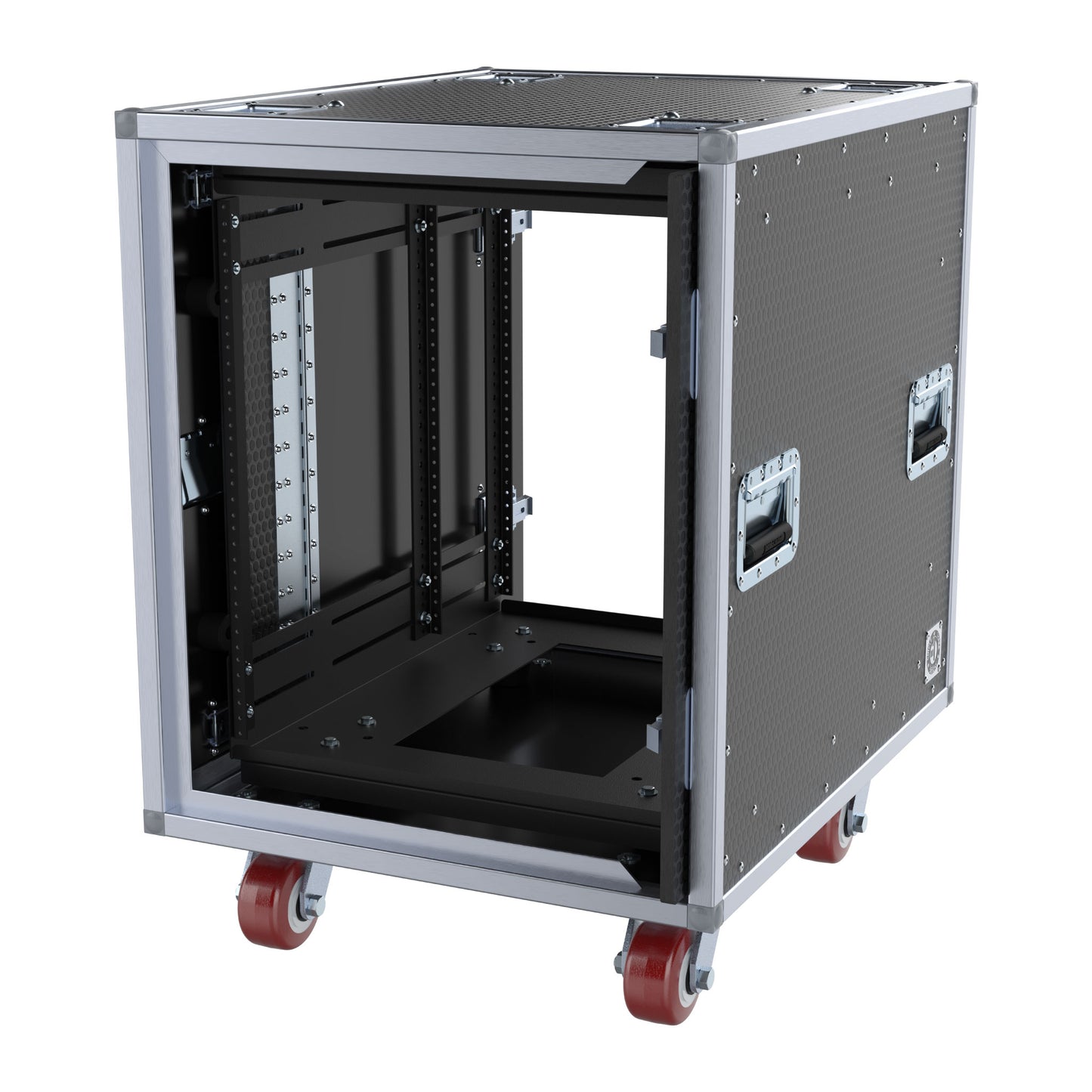

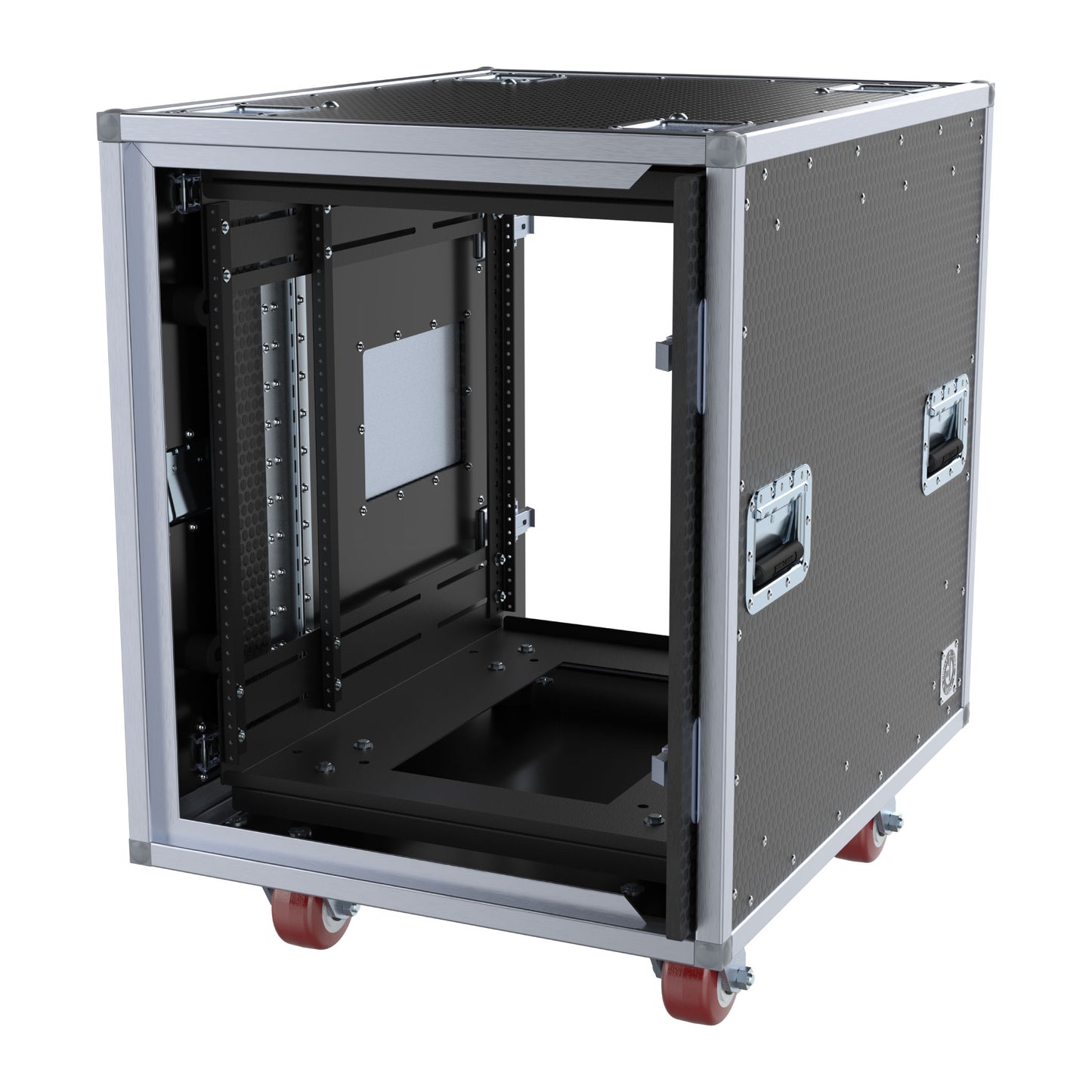

CPAC Pocket Door Shockmount - Single Wide

CPAC Pocket Door Shockmount - Single Wide

Standard Features

Standard Features

Design: Available with pocket doors or removable lids that can hang off the side of the case.

Dimensions: Pocket Door Racks: 24" x 30" footprint. Removable Lid Racks: 22.5" x 30" footprint.

Handles: Pocket Door Racks: 4 handles (2 on each long side of the case). Removable Lid Racks: 8 handles (2 on each side of the case).

Latches: Pocket Door Racks: 2 slam latches on racks from 10RU - 24RU. Racks larger than 24RU require 3 lever latches. Removable Lid Racks: 2 lever latches.

Label Dish: 1 recessed label dish (perfect for dry-erase PAL labels).

Casters: Four extra heavy duty 4" casters (non-locking) each rated at 750 pounds. All cases come with a full length 3/4" Baltic Birch caster pallet.

Caster Cups: Stacking caster cups come standard on the cases and are used for stacking "like sized" cases.

Frame: Proprietary aerospace grade aluminum frame. On pocket door racks, the aluminum frame can be lifted off allowing for full access to the rack when building out your systems.

Rack: Proprietary steel frame that allows for adjustable (front to back) rack rails.

Foam: There is no foam in this case which allows for increased air flow. All shock protection is designed through mechanical distortion uncoupling devices.

Rack Rails: 3 sets of rack rails per rack. Rack rails are tapped at 10/32 UNF. Rack rails are adjustable (front to back). The maximum front rack rail to rear rack rail depth is 24". With the rack rails extended in there maximum outward position, there is 2.125" of space between the rack rail and the lid.

Case Construction

Case Construction

Material: 1/2" Finnish Birch plywood with black phenolic resin. This 100% Finnish Birch plywood is made specifically to our specifications. The exterior phenolic resin has a “circle grip” pattern compared to the typical “haircell” pattern found on ABS. Unlike ABS, the phenolic resin will never delaminate.

Rivets: All of the rivets are backed by steel washers or with the aluminum extrusion.

Welding: The extrusions are welded at key joints in order to significantly strengthen the case.

CNC / CAD: Every case starts off life as a detailed CAD model before it hits the manufacturing floor. Panels are precisely machined using state of the art CNC technology affording us the ability to consistently provide uniformity and repeatability. Aluminum extrusion lengths are calculated using CAD modeling systems to ensure a proper fit and are cut using digital technology.

Additional Options

Additional Options

- 2 locking casters.

Pocket Door Rack Dimensions

Pocket Door Rack Dimensions

- 10RU (24” x 30” x 30”H)

- 12RU (24” x 30” x 33.5”H)

- 12RU (24” x 30” x 33.5”H)

- 14RU (24” x 30” x 37”H)

- 16RU (24” x 30” x 40.5”H)

- 18RU (24” x 30” x 44”H)

- 20RU (24” x 30” x 47.5”H)

- 22RU (24” x 30” x 51”H)

- 24RU (24” x 30” x 54.5”H)

- 26RU (24” x 30” x 58”H)

- 28RU (24” x 30” x 61.5”H)

- 30RU (24” x 30” x 65”H)